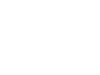

1. Precision assembly

All the core components of the machine have gone through the quality inspection and entered the assembly process, we use modular assembly process, through the standardised operating instructions to regulate each step of the operation:

key structural components using CNC equipment to assist in positioning, strict control of component tolerances, to ensure the stability of the machine's operation;

Intelligent cabling and circuitry integration by senior technicians to operate, in strict compliance with the safety standards, to reduce the risk of failure in the later stage;

for the angle of the serve For core functions such as serve angle calibration and tension presetting, preliminary debugging is completed simultaneously during the assembly process to ensure that the basic performance is up to standard.